Understanding Shaft Couplings in Mechanical Systems #

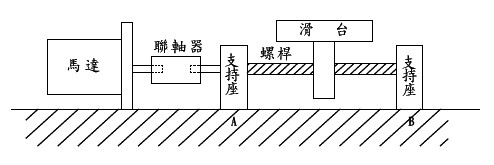

Shaft couplings are essential mechanical devices designed to connect two shafts, enabling them to rotate together and transmit torque safely. Their primary function is to ensure efficient power transmission while accommodating various installation and operational challenges.

Types of Shaft Couplings #

Shaft couplings are generally categorized into two main types:

-

Flexible Shaft Couplings:

- Ideal when perfect shaft alignment is difficult or when installation is straightforward.

- Absorb shocks, accommodate parallel and angular misalignment, and enhance power transmission characteristics.

- Help prevent undue stress on bearings even with slight misalignments.

- Widely used across various industries due to their versatility.

-

Rigid Shaft Couplings:

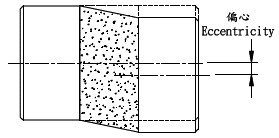

- Provide a solid connection between two shafts, unable to accommodate eccentricity or angular misalignment.

- Require high concentricity and precise alignment during installation.

Key Considerations for Selecting Shaft Couplings #

When selecting a shaft coupling, it is important to evaluate several factors to ensure compatibility and optimal performance:

- Torque Capacity:

- The coupling’s torque rating should be at least twice the maximum transmitted torque. For example, for a 5 N·m torque, select a coupling rated for 10 N·m.

- Steel couplings are often preferred for higher torque requirements.

- Flexibility vs. Rigidity:

- Flexible couplings can absorb misalignments and axial displacement, while rigid couplings require precise alignment.

- Environmental Conditions:

- Consider material properties such as resistance to acids, alkalis, and temperature extremes.

- Backlash:

- Assess whether the coupling introduces any backlash into the system.

- Insulation:

- Determine if electrical insulation is necessary.

- Shock Resistance:

- Evaluate the coupling’s ability to withstand mechanical shocks.

- Maximum Allowable Speed:

- Ensure the coupling can handle the system’s rotational speed.

- Safety Features:

- Look for features that enhance operational safety.

- Bore Range Compatibility:

- Confirm that the coupling’s bore size matches your application requirements.

Shaft Coupling Connection Methods #

There are two primary methods for connecting shaft couplings:

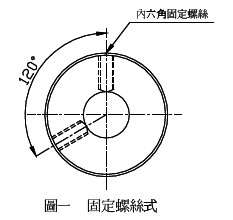

- Set Screw Type:

- Utilizes four set screws positioned at 120° or 90° angles to secure the coupling to the shaft.

- Simple design, cost-effective, but may leave marks on the shaft surface.

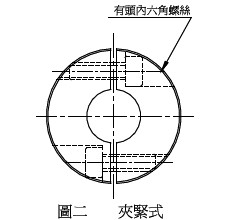

- Clamping Type:

- Features grooves on both sides for elasticity, with two or four hex head screws inserted on either side.

- Easy to assemble and disassemble, does not damage the shaft, and provides stable, secure connections.

Flexible shaft couplings are available in various standard bore sizes and can be customized with keyways. For high-power transmissions, couplings with machined keyways are recommended to prevent slippage, especially for shafts larger than 32 mm in diameter. Always consult the product specifications for allowable values.

Proper installation, alignment, and balancing are crucial to prevent excessive vibration, abnormal operation, or damage to motors and coupling components, thereby extending the lifespan of the mechanical system.

Common Terminology in Shaft Coupling Applications #

- Parallel Misalignment:

- The offset between two connected shafts.

-

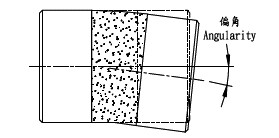

- Angular Misalignment:

- The angular deviation between two connected shafts.

-

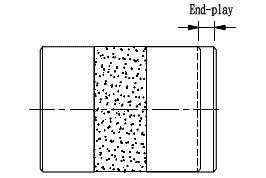

- Axial Displacement:

- The movement of both shafts along their axis when connected.

-

Professional Manufacturing:

- Ballscrew Actuator

- Ballscrew Support Unit

- Motor Bracket

- Lock Nut

- Nut Bracket

- Coupling

Contact Information:

SYK Taiwan Headquarters

Sonyung Industry Co., Ltd.

No. 9, Lugong N. 5th Rd., Lugang Township, Changhua County 50544, Taiwan

TEL: 886-4-7812698

FAX: 886-4-7812458

E-MAIL: syk090@syk.tw

SKYPE: syk090@syk.tw

SYK China Branch

Shanghai Sonyung Trading Co., Ltd.

No. 588, Beisong Road, Minhang District, Shanghai, China

TEL: +86-21-64760638

FAX: +86-21-64760992

E-MAIL: sean@syk.tw

SKYPE: sean@syk.tw

SGS-C Flexible Shaft Coupling

SGS-C Flexible Shaft Coupling SGL-C Flexible rigid shaft coupling

SGL-C Flexible rigid shaft coupling Motor shaft coupling

Motor shaft coupling