Understanding Ball Screw Support Units for Precision Machinery #

Ball screw support units are essential components in linear motion systems, providing secure and stable support for the ends of ball screws. These units are designed to withstand axial loads generated during operation, ensuring the precision and reliability required in applications such as CNC machines, industrial robots, and precision stages.

Product Series Overview #

SYK offers a versatile range of ball screw support units tailored to various load requirements:

These support units are available in different precision classes (C3, C5, C7) to match the grade of the ball screw used in your equipment. Each unit is engineered for structural stability and reliable performance, minimizing vibrations, reducing backlash, and enhancing overall accuracy.

Structure and Features #

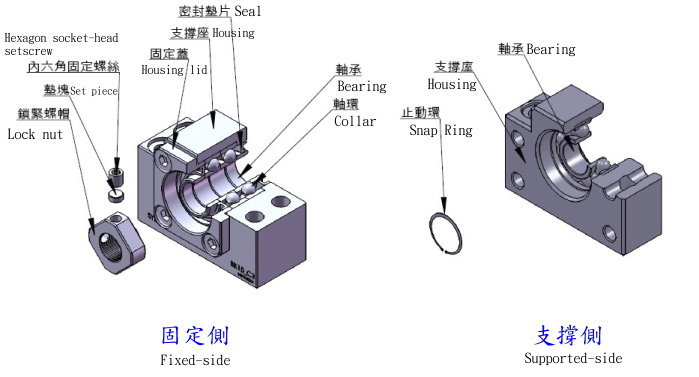

Ball screw support units, also referred to as support bearings or support blocks, consist of several key components:

- Bearing Housing

- Bearings

- Preload Mechanism

- Mounting Arrangement

By integrating these elements, the units ensure optimal functionality and longevity in demanding environments.

Support unit types include: EK, EF, BK, BF, FK, FF, AK, and AF.

Step-by-Step Mounting Procedures #

1. Mounting the Support Unit to the Ball Screw Shaft #

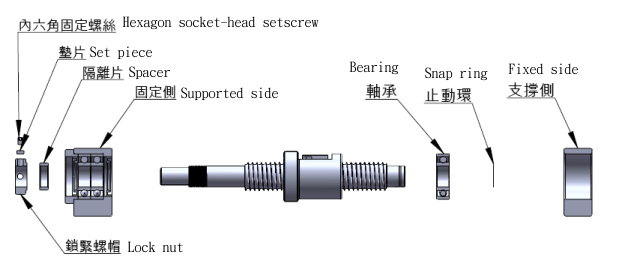

- Attach the fixed-end support unit to the ball screw shaft without disassembling the unit.

- When inserting the screw shaft, avoid damaging the oil-seal lip.

- After inserting the shaft into the fixed-side support unit, tighten the lock nut with the set piece and hexagon socket-head setscrew.

- For special environments, please contact us.

- Mount the bearing of the supported side onto the screw shaft and secure it with a snap ring before inserting the assembly into the supported-side housing.

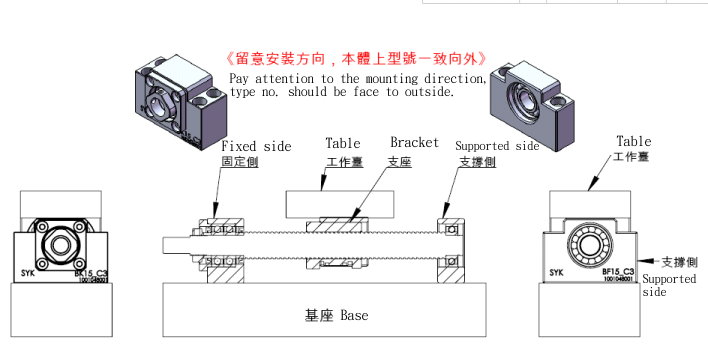

2. Mounting the Table and Support Units #

- Temporarily fasten the ball screw nut to the table. If using a bracket, insert the nut into the bracket first.

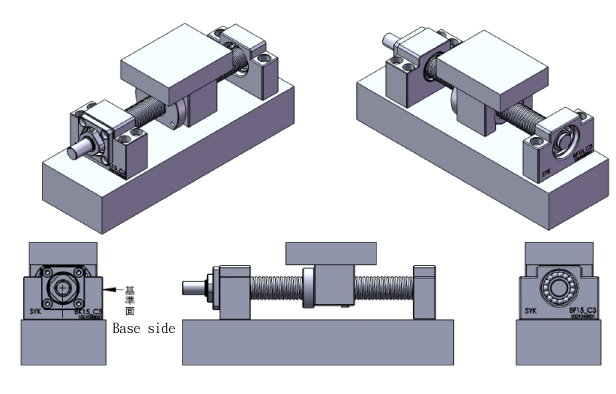

- Mount the fixed-side support unit onto the ball screw shaft and temporarily fasten it to the base.

- Mount the supported-side support unit and secure with a snap ring, then insert the assembly into the supported-side housing.

- Adjust the alignment between the table guide face and the ball screw to ensure parallel accuracy. Fasten both support units to the base.

- Center the ball screw shaft by moving the table toward the supported-side support unit, checking for smooth movement, and then temporarily fasten the system to the base.

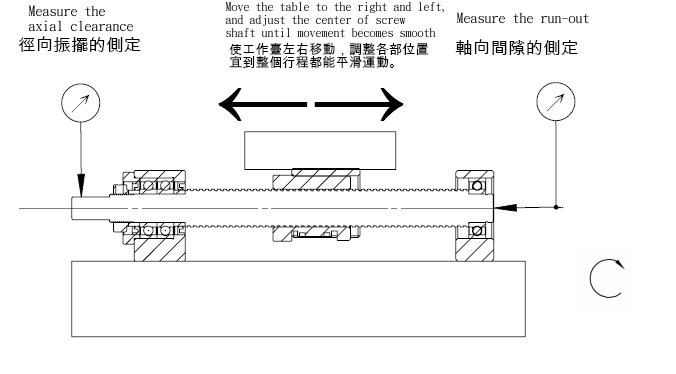

3. Checking Accuracy #

- Use indicators to check the run-out error at the end of the ball screw shaft and to measure axial clearance. For more information on axial clearance, contact us.

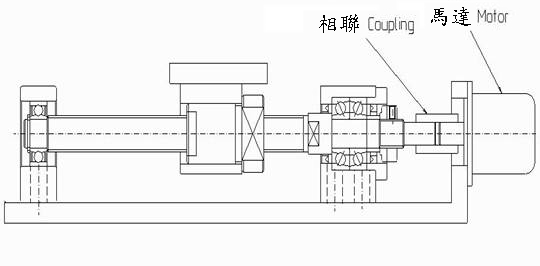

4. Connecting to the Motor #

- Secure the motor to the machine.

- Connect the ball screw to the motor using a coupling, ensuring proper alignment.

- Test the motor operation to confirm correct installation.

Applications #

Ball screw support units are widely used in:

- CNC machines

- Industrial robots

- Precision stages

- Machinery requiring precise linear motion control

Contact Information #

For custom ball screw end support designs or further technical assistance, please contact us.

SYK Taiwan Headquarters

Sonyung Industry Co., Ltd.

No. 9, Lugong N. 5th Rd., Lugang Township, Changhua County 50544, Taiwan

TEL: 886-4-7812698

FAX: 886-4-7812458

E-MAIL: syk090@syk.tw

SKYPE: syk090@syk.tw

SYK China Branch

Shanghai Sonyung Trading Co., Ltd.

No. 588, Beisong Road, Minhang District, Shanghai, China

TEL: +86-21-64760638

FAX: +86-21-64760992

E-MAIL: sean@syk.tw

SKYPE: sean@syk.tw

General Fixed Side Series

General Fixed Side Series General Supported Side Series

General Supported Side Series Heavy Load Fixed Side Series

Heavy Load Fixed Side Series