Ensuring Quality Through Advanced Inspection and Testing #

At SYK, we are committed to delivering high-precision motion components by employing rigorous inspection and testing processes. Our comprehensive approach ensures that every product meets demanding standards for accuracy, durability, and reliability.

Measurement Equipment #

We utilize a range of advanced measurement tools to verify the quality of our products:

.files/image002.jpg)

.files/image011.jpg)

.files/image011.jpg)

Key Testing Procedures #

- Salt Spray Test (72 Hours)

- Axial Positioning Repeatability Test

- Thrust Testing

- Bearings Life Testing

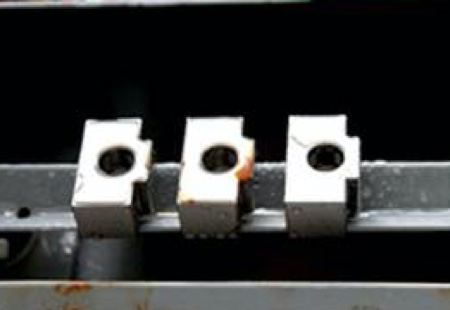

Salt Spray Test #

Objective: To evaluate the corrosion resistance of the nickel-plated surface of support units against salt spray.

Description: The salt spray test uses specialized equipment to simulate harsh environmental conditions, allowing us to assess the corrosion resistance of products or metallic materials. While natural exposure could take a year to show results, the artificial salt spray test can provide comparable outcomes in just 24 hours. This accelerated testing method is essential for evaluating product quality and durability in corrosive environments.

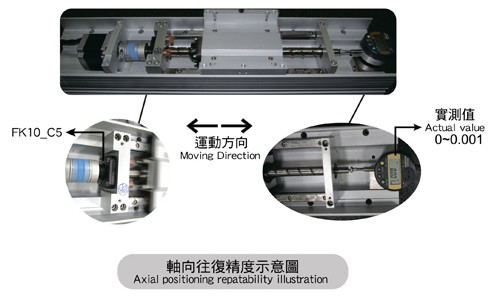

Axial Positioning Repeatability Test #

Description: Our C5 grade support units are equipped with precision angular contact ball bearings and axial preload. This configuration enhances system rigidity and improves both positioning repeatability and accuracy, making it indispensable for high-precision machinery.

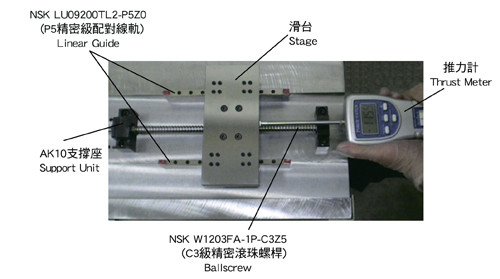

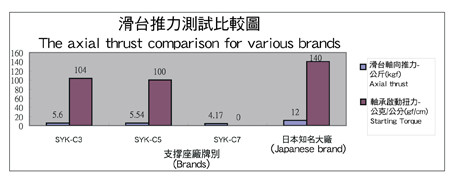

Thrust Testing #

Objective: To achieve optimal bearing starting torque by controlling the preload of the fixed-side support unit.

Key Points:

- Insufficient preload can result in axial clearance and reduced rigidity.

- Excessive preload may cause overheating, increased starting torque, reduced motor efficiency, higher bearing temperatures, and shorter bearing life.

Bearings Life Testing #

Objective: To compare the lifespan of bearings from various brands under maximum axial load, providing statistically significant results in a shorter timeframe than standard testing conditions.

Note: This accelerated life test allows for efficient evaluation and comparison of bearing durability, supporting our commitment to quality and reliability.

SYK specializes in the professional manufacturing of Ballscrew Actuators, Ballscrew Support Units, Motor Brackets, Lock Nuts, Nut Brackets, and Couplings.

Contact Information:

SYK Taiwan Headquarters

Sonyung Industry Co., Ltd.

No. 9, Lugong N. 5th Rd., Lugang Township, Changhua County 50544, Taiwan

TEL: 886-4-7812698

FAX: 886-4-7812458

E-MAIL: syk090@syk.tw

SKYPE: syk090@syk.tw

SYK China Branch

Shanghai Sonyung Trading Co., Ltd.

No. 588, Beisong Road, Minhang District, Shanghai, China

TEL: +86-21-64760638

FAX: +86-21-64760992

E-MAIL: sean@syk.tw

SKYPE: sean@syk.tw